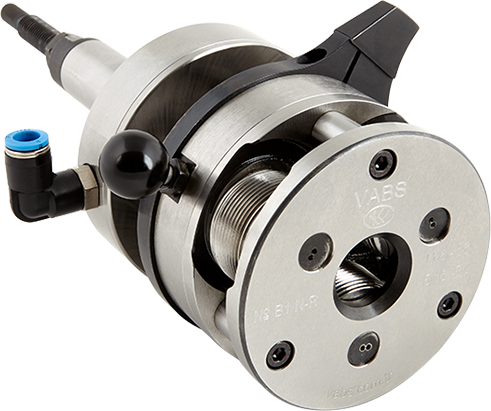

Axial Thread Rolling Heads

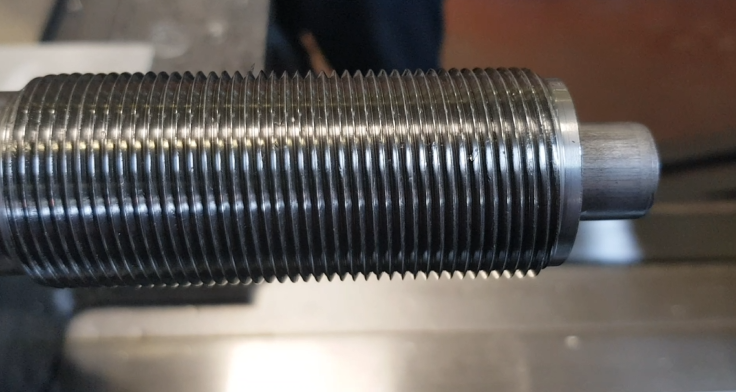

Axial Thread Rolling Heads are a system that enables the fast, precise, and chip-free production of short and infinite thread forms. Operating on the principle of axial (linear) motion, this system completes the threading process by rotating either the workpiece or the thread rolling tool. Compared to the cutting method, the thread rolling device offers up to 90% faster production.

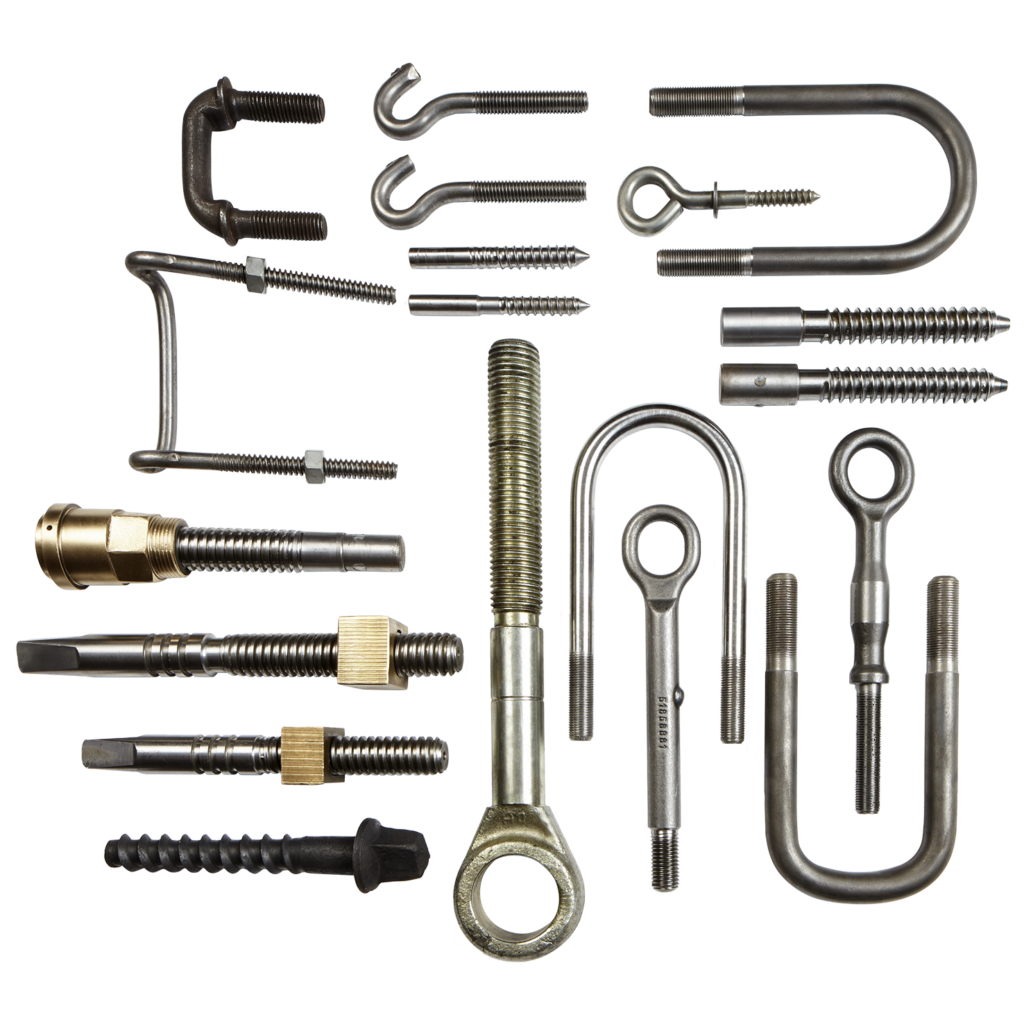

This technology, which compresses the material’s molecular structure without cutting it, provides high durability, material savings, and excellent surface quality. It can be easily used in various industries such as automotive parts, machinery parts production, hydraulic-pneumatic nipples, drilling pipes, construction, and rail systems. It is an ideal solution for those looking to enhance productivity and quality in their manufacturing processes.

Why Use Axial Thread Rolling Head

# Long Tool Life

Low cost with minimal maintenance requirements.

#

Chipless Machining

#

High Production Speed

#

Highest Durability

#

Improved Surface Quality

AXIAL THREAD ROLLING HEAD TYPES

B1-NR / M8-M16

Thread Rolling Head

Compatible Machine Types:

B2-DNİR / M12-M22

Thread Rolling Head

Compatible Machine Types:

B1-NİR / M8-M16

Thread Rolling Head

Compatible Machine Types:

C5-NRÖ / M85-M115

Thread Rolling Head

Compatible Machine Types:

Materials that can be processed with VABS Thread Rolling Heads:

Steel, Aluminum, Titanium and other types, tool steels, stainless steels, cast steels, malleable cast iron, high-temperature materials, nickel alloys, copper, copper alloys (brass), zinc alloys, general structural steels, surface-hardened steel, nitriding steels, heat-treated steels, carburized steels, Inconel 600, Hastelloy.

A001-NR / M2,6-M4

Thread Rolling Head

Compatible Machine Types:

A01-NR / M3,5-M6

Thread Rolling Head

Compatible Machine Types:

A1-NR / M5-M8

Thread Rolling Head

Compatible Machine Types:

B1-NR – İNOV / M8-M16

Thread Rolling Head

Compatible Machine Types:

VABS Vida Dişi Ovalama Aparatları ile oluşturalabilecek diş türlerinin dünya standartları

- Metrik ISO (Metric ISO Thread)

- Whitworth (Whitworth Thread)

- MJ-Gewinde (MJ Thread – Havacılık ve Uzay Sanayi İçin)

- Metrik Koniği Dış Diş (Metric Tapered External Thread)

- Whitworth Boru Dişi – Silindirik (Cylindrical Whitworth-Pipe Thread)

- Whitworth Boru Dişi – Konik (Tapered Whitworth-Pipe Thread)

- Bicycle Thread (Bisiklet ve Motosiklet Vidaları İçin Standart Diş Profili)

- G (BSP – British Standard Pipe)

- R, Rp (ISO Boru Dişleri – İç ve Dış)

- Trapez Diş (Metric ISO Trapezoidal Thread)

- ACME Diş (Acme Thread)

- Trifon Diş (Buttress Thread – Testere Dişli Vida Profili)

- Unified Diş Standartları (UNC, UNF, UNEF, UNJ)

- API Petrol ve Gaz Endüstrisi Dişleri (API Thread)

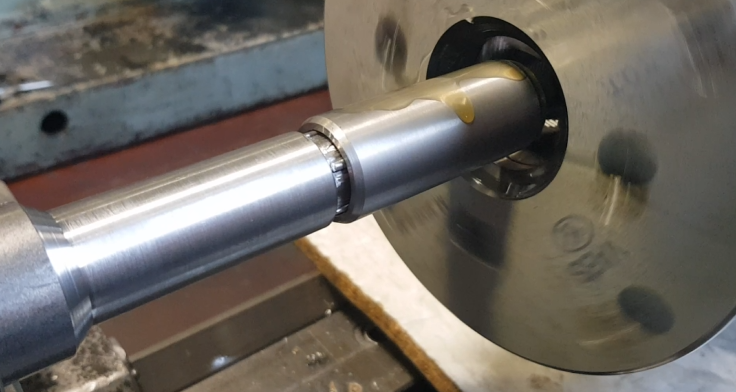

How Does Axial Thread Rolling Head Work?

The Axial Thread Rolling Head creates threads on a workpiece quickly and efficiently. During the process:

Thread Rolling

The rolls rotate on the horizontal axis and advance the workpiece by one thread pitch. This process continues until the thread-cutting distance is reached, completing the thread rolling process rapidly.

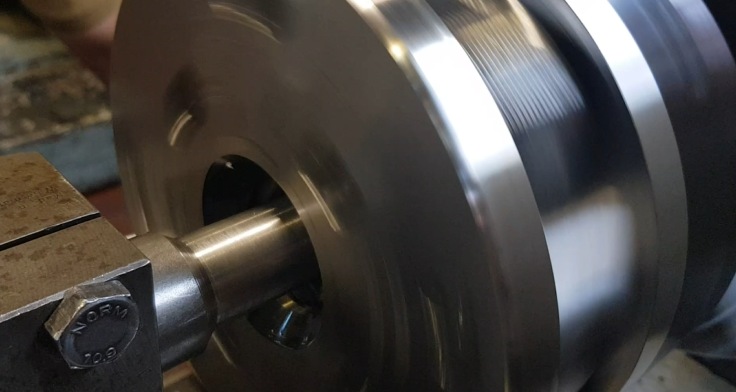

Precision Machining

While the workpiece remains stationary, the head rotates (or vice versa), and the thread is processed without any limitation on thread length.

Chipless Forming

Material fibers are condensed without being cut.

Example Application: Automotive Part Rolling Process

The caliper adjustment screw used in the vehicle’s drivetrain, with a 3-thread M 36×2, will be rolled on a universal lathe.

Workpiece Fixing:

- The workpiece is fixed by the grooves inside the hole, ensuring accurate positioning.

- The fixing process is carried out to prevent movement during machining and to maintain precision.

Starting the Process:

- The thread rolling head is lightly pressed into contact with the workpiece.

- The head then rotates to begin the thread rolling operation.

Thread Rolling Process:

- The head processes the M36 x 2 (3-thread) thread quickly and precisely without chips.

- Once the process is complete, the head automatically releases, and the relay mechanism allows the head to open out from the thread diameter.

Removing the Workpiece:

- The workpiece, with the thread cutting operation completed, is easily removed from the head.

- No damage is caused to the workpiece during this process, and no additional cleaning is required afterward.

Technical Advantages

Usage Area

Axial Thread Rolling Heads are ideal for the following applications: