Veysel Kütüklü Makina Sanayi ve Ticaret Anonim Şirketi

Beginning and Laying of the Foundations (1960-1968)

10%

Expansion in the Industry and Initial Successes (1970-1986)

30%

Innovation and National Growth (1990-1998)

50%

Reaching International Standards (2000-2010)

80%

Leadership and Sustainable Success (2010-Present)

100%

Beginning and Laying of the Foundations (1960-1968)

The foundation of the company is based on the knowledge and experience that Veysel Kütüklü gained from his work as a lathe master in Germany, which he brought back with him after returning to Turkey in 1960.

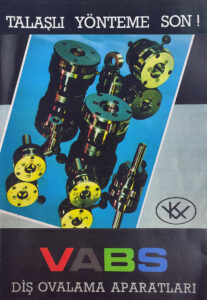

In 1968, with this knowledge and experience, Veysel Kütüklü founded his workshop in Topçular, Bayrampaşa, Turkey, with the principles of quality production and honesty. There, he began producing Turkey’s first domestic thread rolling tools.

VABS thread rolling tools became a product that allowed for raw material savings and the production of high-quality screw threads, thus securing its place in the industry.

Expansion in the Industry and Initial Successes (1970-1986)

In the 1970s, VABS started producing automotive spare parts for automobile factories. Using screw thread rolling tools, the company produced the threads of automotive parts with the highest quality and precision, thereby enhancing the safety of these parts.

Additionally, for over twenty years, Veysel Kütüklü provided the highest-quality mold and spare part support required for pharmaceutical production for international companies such as Pfizer, Novartis, Abdi İbrahim, and Abbott. The production processes for these parts involved using worm rollers or thread rolling tools.

1980s

In response to demand from the automotive and machinery industries, the domestic sales of screw thread rolling tools began. Companies transitioned rapidly to this system due to the challenges of traditional chip-cutting thread manufacturing methods.

1986

In this year, VABS participated in its first exhibition at the Izmir International Fair, the largest fair in Turkey. With this participation, the product applications expanded to various sectors. Automotive parts, pneumatic-hydraulic piston rods, and square screws used in the valve industry were some examples of these new applications.

Innovation and National Growth (1990-1998)

1990

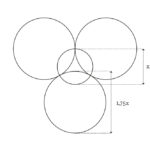

Based on the demand for screw thread rolling tools, development efforts were made, and for the construction sector, telescopic probe tubes were produced using the thread rolling method. The method replaced chip-cutting techniques, transforming probe systems into stronger systems with higher safety. With this innovation, production times were reduced from 5 minutes to 5 seconds. The apparatus systems were first produced in groups of 4-5-6 to zero out ovality in the tubes.

1995

With new innovations, the variety of tools increased, and new designs were created for drilling pipe systems using 5-6 group tools.

1998

Based on demand from abroad, exports of tools began.

Reaching International Standards (2000-2010)

2000

2000

VABS gained the ability to produce according to all thread standards with the thread rolling method, including metric, fine metric, UNC, UNF, UNJF, Whitworth, BSP, BSPT, NPT, trapezoidal, trifon, bicycle threads, and rod-end threads, along with special patterns such as worm, multiple worm, and round threads.

Leadership and Sustainable Success (2010-Present)

2010

VABS products can be safely used on all types of CNC lathes, universal lathes, automatic machines, drilling machines, and non-conventional turning systems. The rolling method ensures the creation of hard threads and surface polish through molecular compression, delivering the highest-quality screw production. Additionally, raw material savings and up to 70% efficiency improvement can be achieved using this method.

Today, VABS operates in a facility of 5,700 square meters, with 2,000 square meters of covered space, located in the Ümraniye Organized Industrial Zone. The company is a leader in thread rolling tools production and is committed to providing reliable, effective, and innovative products to its customers.

VABS aims to be a global reference point for quality and reliability, placing customer satisfaction at the forefront. Continuously following the latest technologies, the company integrates innovative solutions into its business processes to maintain its leadership in the industry.

The most important driving force behind Veysel Kütüklü’s success in this journey, which started with modest steps, is undoubtedly the sincere and reliable approach built in all of his relationships.

Veysel Kütüklü considers himself the industrial partner of his customers and anticipates their needs, providing tailored solutions to meet those needs.