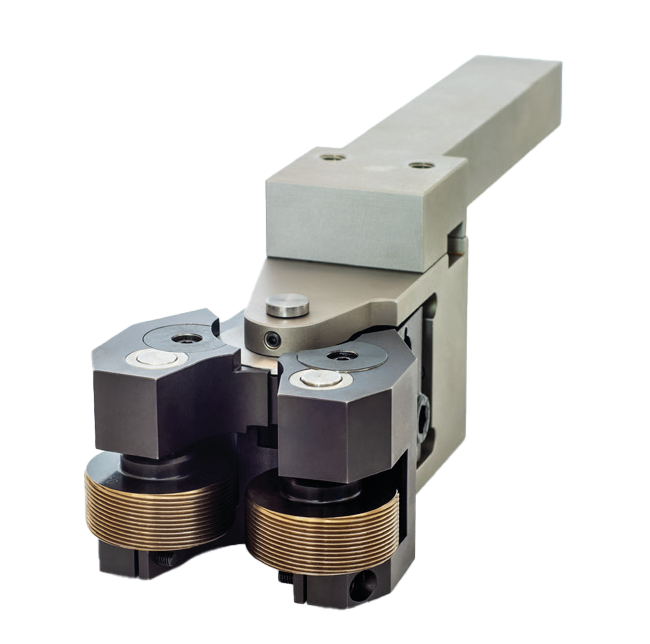

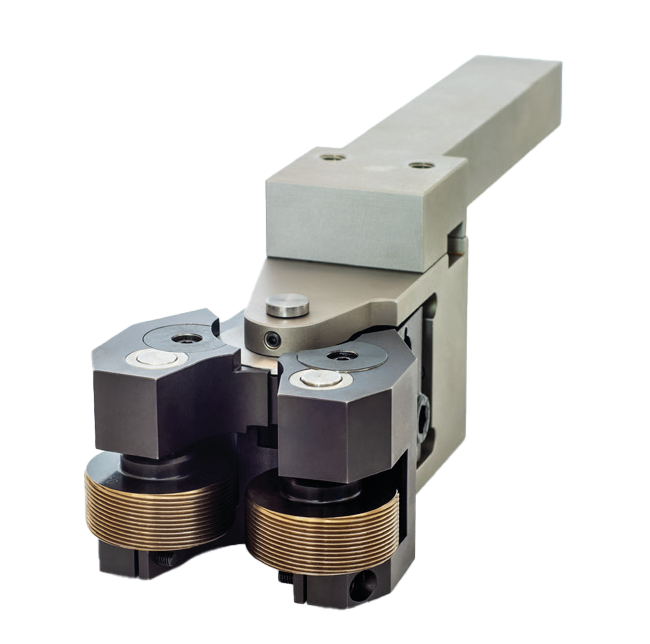

Tangential Thread Rolling Heads

Tangential Thread Rolling Heads are compact tools designed to produce high precision and smooth surface quality, especially for short screw threads and parts where the thread gap must approach zero in stepped components. This tool operates by approaching the workpiece at a tangential angle, offering a no cutting technology that preserves material fibers and provides a clean, fast, and cost-effective solution.

Preferred for precise engineering applications, the Tangential Rolling Head can be easily used on both automatic and CNC machines.

Why Use The Tangential Thread Rolling Heads

# Long Tool Life

Low cost with minimal maintenance requirements.

#

Fast and Precise Processing

#

Compact Design

#

High Quality

#

Flexible Setup

How Does The Tangential Thread Rolling Head Works

Tangential Motion

The tool approaches the workpiece at a 90° angle.

Thread Formation

As the rollers move in a straight line, the thread cutting process is carried out with a tangential motion.

Finishing Process

The process is completed when the centerlines of the workpiece and roller align (typically 10-35 revolutions).