WHAT IS VABS?

VABS is a product designed to shape the thread surfaces of screws, to provide higher performance and durability. Being a solution that enhances the surface quality of screws and increases production efficiency, it found immense application across various industrial manufacturing processes.

%

1

Increase On Hardness Of The Material

1

+

Different Material Type

%

1

Increase compared to traditional methods

1

+

Polishing Rolls in Thread Standard

WHY VABS?

Special Thread Rolling solutions for your production.

Explore our manufacturing process and provide additional value for your screws.

Increase productivity by 90% with VABS compared to the cutting process.

01

SAVES TIME

VABS devices offer very fast thread rolling process allowing time savings up to 90% in production.

02

EASE OF USE

The rolling heads can be used on any type of lathe and CNC machine. In comparison to the cutting operation there is a big reduction of machine operating time. The rolling process takes only a few seconds to be done.

03

DECREASES MATERIAL USAGE

Thread rolling system provided by VABS devices is more efficient in comparison to the cutting process and allows savings in raw material consumption.

04

INCREASES PRODUCTION QUALITY

Thread rolling method offered by VABS, increases thread hardness and surface radiance. With this way it provides long-lasting and higher quality screw manufacturing.

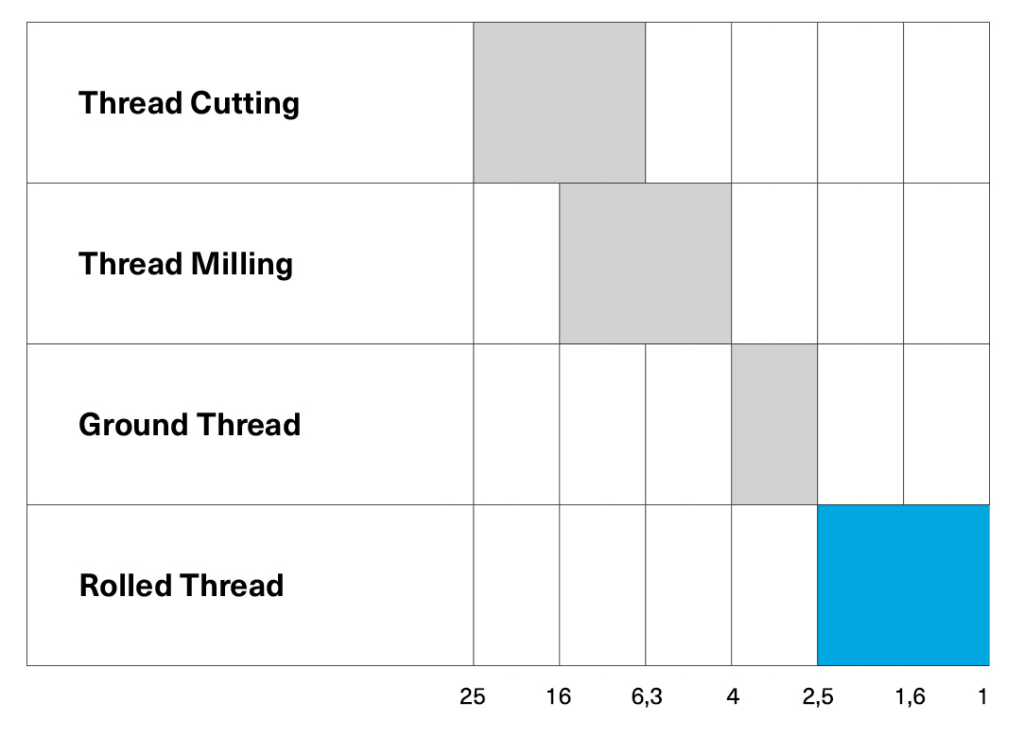

Exceptional surface results provided by VABS

Best possible thread surface quality compared to other methods.

Yüzey Pürüzsüzlüğü

30% INCREASE ON HARDNESS OF THE MATERIAL

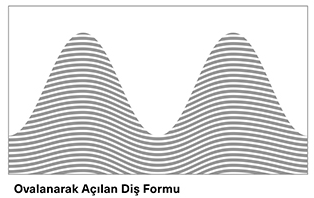

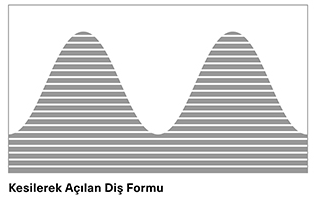

The rolling method offered by VABS increases the material’s hardness by displacing the grain structure’s form. In other words, VABS increases material hardness by 30% when compared to other methods

Cut Thread

Rolled Head